|

Outbound travellers

|

I needed a new hobby to help me cope with the restrictions due to the Covid lockdowns, some sort of activity that would provide mental stimulation, be potentially open-ended, and enhance my employability. And in a nutshell such are the main reasons for my decision to begin studying Hungarian. Indisputably acquiring a language, even one's mothertongue, can be a lifelong venture. Vocabulary is limitless. Libraries are ever expanding their selections. Language study is certainly a means of maintaining brain plasticity. I also wanted to test some of the methods that I have been encouraging my students to use while they improved their English speaking abilities while also developing new ideas gained through my own study process.

|

German, English, French Speaking Clubs

|

Another upside that I had not immediately anticipated was that studying uncommon languages potentially creates social connections amongst those who do the same. I needed to set some reasonable goals for myself and one was travelling to Hungary to put my language acquisition to the test. I admit that I am still far from conversant in this language; nevertheless, I did meet with some limited success.

On October 11th, the wife and I set off from Shanghai Pudong after travelling from Nanjing to spend the night in an airport hotel to fly out at 09:30 onto our first leg in Zurich. We ended up going through passport control in Zurich and made the mistake of getting a room in a hotel close to the airport instead of just settling into the airport facilities for those with long layovers. Live and learn. The Zurich airport, nonetheless, was quite easy to orient ourselves through, even though Julia had some containers of liquids confiscated because she didn't remove them from her carryon. Live and learn. x2

|

Study Hungarian and become a millionaire

|

It was a brief hop onto the Budapest airport where I first began encountering Hungarian in its natural environment. I found myself pleasantly pleased by my ability to comprehend the signage. Our first challenge was discovering that our credit card technology was not updated to European standards. Most merchants only use credit card readers that rely on embedded chips that can be tapped to complete a transaction. Swiping is an increasingly obsolete technology, it seems. Fortunately Julia was able to work with one of the shuttle bus workers to buy the necessary tickets in order to wend our way across the city to our B&B on the Buda side. |

Trilingual signage customized for our arrival

|

The ride to our residence was an intense introduction to the landmarks and sights which awaited us. After settling in, it seemed like time to taste some of the local specialties. We strolled around the neighborhood until we stumbled up the Dérnyé Bistztró. I ordered the Lecsó and Julia got the French Onion soup. Sadly, the soup was overly salted with rubbery cheese, definitely not Gruyère, which covered a massive hunk of bread that failed to come apart with a spoon. Recipe failure.

|

Cheesy French onion soup

|

`The Lecsó, which is often translated as ratatouille (no, it's not at all), was rather good, sautéed capsicums, tomatoes, and onions with an in-house bread. It went well with a local craft ale, Fóti Pils. I boldly went ahead and indulged by ordering the túrós gomboc. Even the single gomboc was more than I could consume. Túró is basic cheese curd which is why it is often translated as cottage cheese or quark. It's mixed with bread crumbs and then poached and then was served with a yogurt, heavy cream topping with what seemed to be praline topping. Tasty, but the mouthfeel was diminished by grittiness from the breadcrumbs. |

| Finomság |

On our way back to our first B&B in Hungary, we discovered Spar to stock up on groceries and alcohol. It's a good source for all that one needs to make a meal, although Aldi is cheaper. One discovery that is notable and worth sharing is that high quality European beers and wines can be purchased ore cheaply than the domestic Hungarian lagers. I was planning on doing a tasting of the common Hungarian beers e.g. Dreher, Borsodi, Pocsék etc. But then I made an interesting discovery. All of these doubtful beers were more expensive than Pilsner Urquell, which is of a known quality. I must admit that I didn't even try tasting the national industrial brews. It's worth pointing out here that while shopping at Aldi, I found one of the lowest priced reds was a Puglian Primitivo, which made the choice so easy. I did, in fact, but a bottle of Kékfrankos at a higher price point than the Italian reds, but I would not suggest that anybody do so. |

NeoClassical façade of Buda tunnel

|

On Friday the 13th, Julia decided that she needed to buy me a pair of shoes. She found a Birkenstock outlet and we headed there early. The shop carried exactly what I wanted and the service staff had a commendable level of English skills. Budapest, based generally on its level of English communication skills, is an international metropolis. With new shoes in tow, we walked around until Julia found a Turkish/Greek buffet where Julia saw some food on display that appealed to her.  |

Buda Tunnel looking out upon the Lánchíd

|

With our bellies sated, we stumbled around and into the Jewish quarter, a Zsidó négyved. I can now claim to have visited there. We trotted back to our apartment for a rest and to unload. Later at night we went out to a another restaurant, Plántan Grill Étterem, where the multilingual waiter tolerated my attempt to order in the local language. Julia had her coveted goulash/gulyas and and I tried the cíganpecsenye. We walked off the calories with a late night stroll along the Danube.  |

ülõlös étterem

|

|

Szechényi Chain Bridge: Lánchíd, opened 1849

|

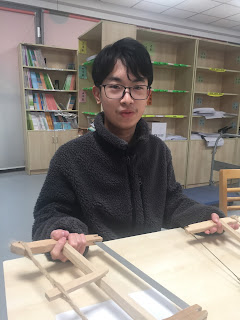

Saturday the 14th, we planned to meet my longtime language exchange partner, Tabi Gabor, who rode a train into the city from Hatvan. We met up on Blaha Lujza tér where I spotted the first McDonald's outlet in Hungary. Just down the street was a Chinese restaurant where he remembered eating years back. It has expanded much since his initial visit. Its interior was completely similar to any from the mainland. Gabor let Julia order and he even seemed to enjoy the boned chicken feet and steamed whole fish. He was gracious enough to pick up the bill. we spent a goodly amount of time in the restaurant but then we decided to seek out a café to continue our discussions. We treated at the coffeshop but Gabor only chose to drink water.  |

Tabi Gabor appreciating his birthday gift

|

We said our goodbyes as Tabi úr needed to return home to tend to his aging dog. Julia got the idea that she wanted to pass by the Keleti Pályaudvar where we would board a train later to travel to Pécs. We wandered about, not following any clear direction through a rather decrepit section of the city and yet still managed to find it.

|

Kinai étlap

|

|

| The cathedral around a corner from a Chinese restaurant |

|

On Sunday the weather was slightly stormy. After getting a bit lost trying to find a bookstore which seemingly no longer exists, we discovered a restaurant operated by a Fujian family around a corner from the St Stephen's Basilica. Later that same evening we connected with another language exchange partner who was able to spare a few hours to get away from his teaching responsibilities and graduate studies deadlines.

|

| Pécsbe |

|

Keleti Pályaudvar

|

On Wednesday, it was time to relocate to Pécs by train. Despite some confusion with the tickets and how we were charged, we boarded on time and watched as the scenery passed outside the windowpanes. The bigger challenge of the day was finding the B&B located near the university campus on Tibor utca 30A. We encountered a friendly father who was passing by to pick up his children from a nearby primary school. He admitted to struggling to follow the original Hungarian instructions that were translated by the app for us. As we came to understand, 30 was the lot number with segregated plots for different residential housing units. The entrance to our B&B was discovered up a steep hill well off of Tibor utca. This frustration would prove to be foreshadowing. We found a Spar in the neighborhood and stocked up for our stay. |

Pécs streetscape

|

The next day, we decided to explore the covered the farmers' market. This is also where I ordered and tasted my first lángos and where Julia chatted with a Chinese food stall owner. Langós is simply fried bread dough smothered with sour cream and other condiments. I bought two: one with shredded cheese and a second with slivered red onion. After the first bite, my first thought was that this bland mass of carbs and fat needs hot sauce. The dough is fluffy and the crust tears apart readily. And that was that.

|

covered farmers' market

|

|

Flower arrangements

|

|

Paprikák és más zöldségek

|

|

Julia connecting with the Han Chinese diaspora

|

From the market we moved back closer to the city center and found ourselves on a plaza bordered by the Synagogue museum. The building itself is now longer an active synagogue since the Jewish population is too low to require such a large edifice. |

Pécs Jewish life museum built 1869

|

|

| Archway |

|

Cast Iron column

|

|

| Stenciled decoration |

|

|

| Ceiling detail |

|

We then continued exploring the downtown are where we knew that we would return to over the next few days. We returned to the B&B with enough sunlight remaining to enjoy a bottle of kékfrankos outdoors.

|

Zsolnay fountain on Széchenyitér

|

|

School group

|

On Friday morning we headed directly to the Zsolnay Museum. The collection and the building itself display a wealth of visual stimulation. We managed to avoid getting mixed up with the group tours.

|

Architectural ceramics

|

|

Highly trained ducks

|

|

Stenciling

|

|

Zsolnay ceramic tile sample

|

The route thence to the Necropolis is short. While the content might be considered light, the design of walkways is in many ways more interesting which enables visitors to walk over and under the crypts in order to observe the painted interiors and carved tombs. I was much less impressed by the Medieval university building which doesn't even assert was a university. But it might have been. |

Doorway sculpture

|

We found lunch on the central plaza at a Turkish takeout. Julia and I afterwards walked along the outside of the extant citywalls and then reentered the perimeter near the Saint Stephen church where a wedding was underway. |

| drawbridge and arrowslit window |

|

|

| section of medieval city fortifications |

|

|

Father and bride

|

|

Cathedral of Saints Peter and Paul

|

Saturday was so rainy that we decided to rest by staying in. On Sunday we made the decision to cut our visit to Pécs short. The list of complaints with the B&B hostess was growing. According to the description of her rental unit, we expected to meet with her. Even though she lived in the upstairs from us, she only communicated through texts in the app. When the internet service was down, her response was dismissive and rude. She also failed to provide the cleaning supplies that she listed as basic, telling my wife, Julia, when she asked about laundry detergent that this wasn't a 5 star hotel. |

Atlantes on a Pécs street

|

Secondly, I was not able to meet with any of the contacts that I made as part of language exchange. One professor has relocated to accept a job at a different university and a second local English studying gentleman who had been very informative about what to expect in Pécs, casually ghosted me when I confirmed my arrival time. Budapest thus became a better place to be.

|

| Baroquish | |

|

Neglected doorway

|

|

Modern transport

|

|

Former Grocerystore and streetscape

|

After rebooking our tickets at the station, we decided to enjoy our last meal at Fõtér, which overlooks the historic central plaza. We began with a venison soup and a local beer, Pécsi sör lager. Both proved to be good choices. I chose a a chicken tikka masala for Julia to meet her rice needs; whereas, I selected a local cheese and charcuterie platter, a few morsels that helped solidify a positive memory of Pécs. |

View from the main square towards train station

|

|

Pasha Qasim Mosque

|

|

Photo op photo opped

|

When we arrived back in Budapest on Monday, we were booked into a downtown B&B where we could stay for two days until moving to our final lodging during our Hungarian travels. The building embodied all the features of a pre-electric era: large central courtyard, transom windows, and tall ceilings. It's astounding how much of the housing stock in Budapest retain their 19th century structure and decorative details.

|

Detail Keleti Pályaudvar interior

|

|

19th century courtyard view

|

It's easy enough to just poke one's head into a doorway to discover the handiwork and variety.

|

| 19th century vestibule |

|

terrazzo and Greek key motif

|

|

View through a peephole

|

|

Randomly underfoot craftsmanship

|

We relocated on Wednesday to an apartment closer to the Danube and with an equally impressive view. The next day we rode the full length of the M1 line and then walked back along much of its length. The Opera building stands out as a marvel of sculptural ornamentation. |

windowsill detail

|

|

dedicatory muses

|

|

Archway key and metopes

|

|

Random sphinx ornament

|

We got in a last round of souvenir shopping in an underground market, mostly refrigerator magnets. We chose a Vietnamese restaurant to lunch in because the wife needed a dose of rice. I am guessing the cooks have adjusted their recipes to accord with the local lángos eaters. My curry rice was inspid and lacked any flavor of curry spice.

|

Interior Nagy Vásárcsarnok

|

|

Szabadság bridge and tramvae

|

We agreed to meet with a local woman who works as a English tutor at one of her favorite cafés, Green Cukrászda és kávézó, within a short distance of the Nyugati Pályaudvar, another historic train station presently undergoing renovation and upgrades and designed by the same man who created the Statue of Liberty. Gabor would also join us along with his longtime friend, Juhasz Max whose English speaking skills he always compares his own as inferior to.

|

Nyugati Railway Station

|

|

Nyugato Pályaudvar from Eiffel square

|

We spent a good part of the afternoon sipping coffee, tasting a selection of pastries, and chatting, mostly about topics related to Max's globetrotting career path, who has worked in both the USA and the UK in a variety of fields e.g. a CNC operator for a subcontractor to Boeing in CA and a homemover in the UK. We dipped a little bit into in international politics, too. I found that he much more quickly understood the dynamics within an authoritarian system as I spoke about the ongoing downward spiral in the PRC. He admitted that he didn't follow Hungarian and yet conceded that area where he lives is reliably supportive of the Fidesz party.

|

Neglected splendor

|

|

Subway Ironwork

|

|

| Memorable Entryway |

|

Tribute to a Germ Theoretician

|

We all were feeling hungry so we decided to make a trek back to the first Chinese restaurant that Gabor introduced us nearby Blaha Lujza tér. The meal progressed with more friendly banter until we bid our last goodbyes. |

Typical Hungarian fare

|

|

PRC allegience

|

Saturday was our last day in Hungary. We arose,packed, departed, and made our way to the airport. Since we had some spare time, we took advantage of the observatory platform and had lunch, experiencing our first yogurt bar. As if to help me experience a throwback to post 9/11 paranoia, the security officers forced me to remove my belt and shoes. Hú, I have lost weight.

|

Roof timbers

|

|

Wooden pavers

|

From Münich to Shanghai the flight felt quicker.

|

Memorial to the Revolution of October 23rd 1956

|

To those who celebrate: Boldog Köztársaság Napját!

|

The musuem displays are citywide

|